2.high performance anticorrosion coatings

3.environmental and eco-friendly

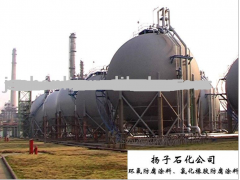

EP Epoxy Heavy-duty Anticorrosion Coatings / fire retardant coating

Design Usage

Designed for various storage tank, pipe and steel structure of petroleum chemicals, metallurgy and coal tar systems, both for new structures and maintenance of existing structures.

The film has excellent adhesion, lubricating oil resistance, gasoline resistance and diesel resistance.

Excellent solvent resistance and resistant property (i.e. humidity, salt fog, mildew resistance).

The film has good hardness and resistance to penetration.

This product is room temperature self dried, applicable to plants without baking facility, steel structure on site and concrete structure with resistance to chemical medicine.

It is not applicable to be exposed to sunshine or hydrofluoric acid or fuming acid environment without weather resistant top coat.

Thereinto,

Shanli 7053: iron red primer, 2K package

Shanli 7054: micaceous iron gray and gray inter coat, 2K package

Shanli 7055: few inert color top coat (gray, white, black, iron red and iron yellow), 2K package

For other coatings or any doubt

Basic Data

Min. dosage: 0.08-0.10kg/m2/layer

Insufficient to form effective system. The film thickness is adjustable while it will influence dosage and drying.

Theoretical dosage: Primer: 0.14-0.17kg/m2

Inter coat: 0.16-0.20kg/m2

Top coat: 0.13-0.15kg/m2

Recommended DFT: Primer: 50μm×2

Inter coat: 60μm×2

Top coat: 45μm×2

Theoretical coverage: Primer: 6.2m2/kg/layer (8.7m2/L/layer)

Inter coat: 6m2/kg/layer (8m2/L/layer)

Top coat: 7m2/kg/layer (8m2/L/layer)

It is necessary to consider proper loss factor.

Tack-free time: ≤1.0h

Recoat interval: Min. 24h, no max.

Curing time: 24h-7d

Flash point: ≥23°C

Storage stability: Min. 12 months sealed in cool and dry place

After 12 months, quality check is necessary before use. Longer storage time would influence application performance.

Far away from heat resource, fire resource and strong oxidizer.

Color and appearance: Accord to standard or key color, color deviation within acceptable limits, and film is flat.

Pot life/h: ≥8

Drying time/h: touch dry≤4, hard dry≤24

3 Physical performances: Impact resistance: 30cm

Flexibility: 3mm

Adhesion: 1

5 Chemical performances: Salt water (3%) resistance: 10d

NaOH(10%) resistance: 10d

H2SO4(10%) resistance: 10d

Toluene resistance: 10d

Gasoline resistance: 30d

No blistering, no cracking-off (complex layers)

Surface Treating

All surfaces to be coated should be clean, dry and unpolluted (free of vapor, dust, oil and rusted chips) and accord to GB8923 (Requirements: reach Sa2.5 or St3, cleanness 95%, surface roughness 40-70 µm. After surface treating and prior to coating 7053 primer, the steel should be re-derusted if being oxidized to reach regulated visual standard. The surface temperature should be 3 °C higher than dew point to prevent vapor condensation.).

Re-derust the weld joint and damaged area and clean pre-coat and polluted area by fresh water, reaching regulated visual standard.

If used for maintenance of original structures, please make matching experiment firstly to get rid of inter-influence.

Prior to coating 7055, please make sure that both 7053 and 7054 are cured completely, and the surface is clean, dry and unpolluted.

If coating on primer or inter coat without complete curing, bleeding, pinhole and other unpredictable deficiencies are possible.