1) Complete thermoforming solution

2) ABS, smooth, fire-retarded or textured

3) Applicable to plastic part, component, etc

1. Application of thermoforming plastic parts technology

With the rapid demand of more diversified products, more and more designers have been considering to use thermoforming technology to make their plastic parts, covers and etc, which features low tooling cost and fast lead time.

Thermoforming, one of the oldest methods of processing plastic material, has also been widely used today to make plastic enclosure, cover, cowl, housing, parts, base, liner, tray, tub, container, case, dome, box, rack, stand, inner liner, component, fitting, accessory, applied in wide industries as Automotive, Agricultural, Building and Construction, Design, Electronic, Machinery, Sanitary industries and etc.

2. Why chooose Honyien Plastics Company for ABS thermoforming plastic part service?

A. Proficient skills and profound knowledge in dealling with thick gauge plastic sheet thermoforming, up to 12mm;

B. Competitively pricing, because of self-supply of thermoforming material: plastic sheets;

C. Seamlessly cooperation with customers to ensure exact fulfillment of all specification.

D. Complete ABS thermoforming plastic part solution: from preliminary project design support, material production to tooling design, making and vacuum formed products manufacturing

E. All types of thermoforming material available: ABS, HIPS, ABS/PMMA, etc. textured, smooth, gloss or matt, fire-retarded or UV resisted

3. Process of contracted ABS thermoforming plastic part manufacturing with Honyien:

A. CAD/3D File Review--The process begins with preliminary review of your design file. To see if your design files are fit for thermoforming technologies, please contact us for first review.

B. Design Assessment--Your design will be thoroughly examined by our assessment team to see how we can best make it with ABS thermoforming plastic part. Proposals will be offered while keeping the best quality and maintaining the integrity of your design to the greatest extent.

C. Product Design Assisting--Our engineer will assist you fulfill your creation, make proposals, translate your drawing into CAD/3D files, if necessary.

D. Tooling--Tight control will be made over the entire tooling process to eliminate the risk of misinterpretation of your concept and other potential problems.

E. Sampling--Quick and accurate sampling will follow to confirm your designs before mass ABS thermoforming plastic part production.

F. Manufacturing--Our ABS thermoforming plastic part manufacturing features fast lead time, exceptional level of details, flexible order volumes.

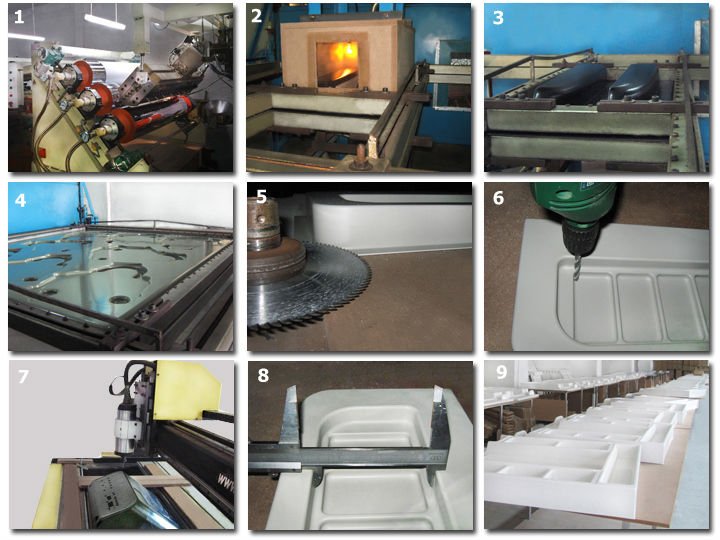

4. ABS thermoforming plastic part process at Honyien:

|

1. Extruding plastic sheet: |

ABS, HIPS, PP, PE, PC, PETG, PMMA resin granules are extruded or co-extruded into thermoplastic sheet--textured, smooth, gloss or matt, fire-retarded or UV resisted |

|

2. Thermoforming to shape: |

After being heated, the plastic sheet is stretched onto or into a mould, and held against the mold by applying vacuum between the mould surface and the sheet to form desired shapes. |

|

3. Cooling to maintain shape: |

Once formed the plastic need to cool before being released from the mould. To speed up the cooling cycle, fans are fitted and activated once the plastic part is formed. |

|

4. Making large product: |

Our machine could be restructured to make larger ABS thermoforming plastic part, with maximun dimensions of 3000*2000*800*12mm (L*W*H*T) |

|

5. Trimming edges: |

Extra material is firstly trimmed before more accurate processing. Sawing is often used in this stages. Polishing is made additioanlly to smoothen the edges. |

|

6. Drilling holes: |

Drilling oftens follow the trimming. Other post forming processes include decoration, printing, strengthening, reinforcing and assembly. |

|

7. CNC Processing: |

For more accurate and faster speed post ABS thermoforming plastic part processing, CNC is often used. The machine is computer programmed to select the correct cutting tools and angle to suit each cutting area. |

|

8. Examination and checking: |

Before packaging, all our ABS thermoforming plastic parts will be carefully checked in terms of dimensions, surface finish, stenghth, colour requirements and so on. |

|

9. Cleansing and Packaging |

All ABS thermoforming plastic parts are cleaned before packaging. Products are wrapped with plastic film to prevent scratches and cartoon boxs are used or other methods are applied as required. |

For more information and support