40 years of manufacturing experience

Al2O3:17~18%,20~30%,65%,92%,95%,99% etc

Size:3~75mm

ISO9001:2000

Product De

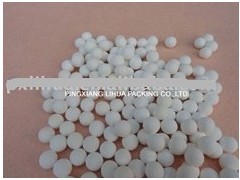

The inert alumina ceramic ball is widely used as the covering or supporting materials of the catalyst in the reactors and the packing in the columns in such varied areas, for example, petroleum, chemical industry, chemical fertilizer, natural gas, and environmental protection etc. There are lots of advantages for it, for instance, the stronger resistance to high temperature and high pressure, lower ratio of the moisture absorbing, more stable chemical properties, and so on. It is capable of enduring the corrosion of acid, alkali, and organic solvent. In addition, it can also bear the rapid transitions of temperature during the operation. In fact, its principal functions are to accelerate the distribution of gas or liquid, and support or protect the active catalyst, which especially has the relevantly lower mechanical strength.

This product, which had been developed by our group company, had gained the award of excellent new product and the prize of the science and technology improvement of Jiangxi province in 1988. Of late years, it has always been recommended by SINOPEC. Since it entered the market, all circles of customers had realized that its properties and effects are the same as the foreign products, and some of the technological index has surpassed the same foreign products.

Chemical composition:

|

Chemical compositions |

Content |

|

AL2O3 |

(Standard value +4) % |

|

AL2O3+SiO2 |

≥92% |

|

Fe2O3 |

<1% |

Physical and chemical properties:

|

Item Type |

Feldstar |

Feldstar-mullit |

Mullite |

Mullite-corundum |

Corundum |

|

|

Chemical |

Al2O3 |

20-30 |

30-45 |

45-70 |

70-90 |

≥90 |

|

Al2O3±SiO2 |

≥90 |

|||||

|

Fe2O3 |

≤1 |

|||||

|

Water absorption % |

≤5 |

|||||

|

Acid resistance % |

≥98 |

|||||

|

Alkali resistance % |

≥80 |

≥82 |

≥85 |

≥90 |

≥95 |

|

|

Thermal resistance |

≥1300 |

≥1400 |

≥1500 |

≥1600 |

≥1700 |

|

|

Crushing strength |

Φ6 |

≥400 |

≥420 |

≥440 |

≥480 |

≥500 |

|

Φ8 |

≥480 |

≥520 |

≥600 |

≥620 |

≥650 |

|

|

Φ10 |

≥600 |

≥700 |

≥800 |

≥900 |

≥1000 |

|

|

Φ13 |

≥1000 |

≥1100 |

≥1300 |

≥1500 |

≥1800 |

|

|

Φ16 |

≥1500 |

≥1600 |

≥1800 |

≥2300 |

≥2600 |

|

|

Φ20 |

≥1800 |

≥2000 |

≥2300 |

≥2800 |

≥3200 |

|

|

Φ25 |

≥2500 |

≥2800 |

≥3200 |

≥3600 |

≥4000 |

|

|

Φ30 |

≥3000 |

≥3200 |

≥3500 |

≥4000 |

≥4500 |

|

|

Φ38 |

≥4000 |

≥4500 |

≥5000 |

≥5500 |

≥6000 |

|

|

Φ50 |

≥6000 |

≥6500 |

≥7000 |

≥8500 |

≥10000 |

|

|

Φ60 |

≥8000 |

≥8500 |

≥9000 |

≥10000 |

≥12000 |

|

|

Φ75 |

≥10000 |

≥11000 |

≥12000 |

≥14000 |

≥15000 |

|

|

Bulk density ,Kg/m3 |

1100-1200 |

1200-1300 |

1300-1400 |

1400-1550 |

≥1550 |

|

|

Note: It may only be provided as the reference for the bulk density, and it is not as the evidence of check. |

||||||

Product Standard:

Chemical Industry Standard HG/T 3683.1 - 2000 Industrial Ceramics Ball - Inert Ceramics ball