Hight quality ceramic part includes Al2O3, ZrO2,SiC, Si3N4 material with precision dimention.

|

Material name |

Volume Density g/cm3 |

Hardess HRA |

Bending strength MPa |

Air hole Rate % |

Thermal expansion Coefficient 1x10-6/°C |

Breaking tenacity (MPa·m1/2) |

Thermal Conductivity W/m·K |

|

SI3N4(RB) |

2.5-2.6 |

80-86 |

160-210 |

<1 |

2.53 |

7 |

10-15 |

|

SI3N4(G.P.S) |

3.2-3.3 |

89-92 |

500-700 |

<0.05 |

3.5 |

7.5 |

15-20 |

|

SI3N4(HP) |

3.4-3.7 |

93-94 |

800-1100 |

<0.01 |

3.8 |

6.5 |

20-25 |

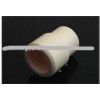

JINGANG structure ceramic includes Al2O3, ZrO2,SiC, Si3N4 material . These advanced ceramic are applicated in sealing material , mechanical system, firing equipment and refreactory.

Advantage:

1. wear-resistanting,

2. resistance to elevated temperatures,

3. corrosion resistance

4. oxidation resistance

Specification

|

Zirconia ceramic are applicated as shaft bearing ,plunger,sealing matetial and knife, with high density, hardess ,bending strength and breaking tenacity. |

|||

|

Zirconia ceramics properties |

Density |

g/cm3 |

6.0 |

|

Water absorption |

% |

<0.05 |

|

|

Firing temperature |

°C |

1550 |

|

|

Hardess |

HV |

1350 |

|

|

Bending strength |

MPa |

950 |

|

|

Compression strength |

Mpa |

25000 |

|

|

Breaking tenacity |

Mpa·m1/2 |

6-8 |

|

|

Thermal expansion coefficient |

/°C |

9.5x10-6 |

|